Meat and Poultry Printing, Marking & Coding

Safety and traceability — New regulations, food safety concerns and retailer demands call for accurate and readable codes.

A true printing partner understands the importance of great print quality and achieving your operational goals in a highly regulated environment. With over four decades of experience in the meat and poultry industry, Videojet offers the perfect combination of technology, expertise and service options to be your coding partner of choice.

- Applications

- Line Integrations

- Documents

- Overview

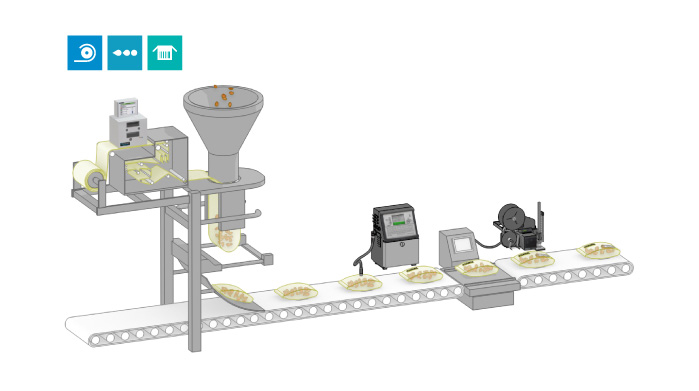

- Trays

- ChubPacks

- Vacuum/Shrink Film

- Bags /Pouches

- Cartons / Sleeves

- Cans / Jars

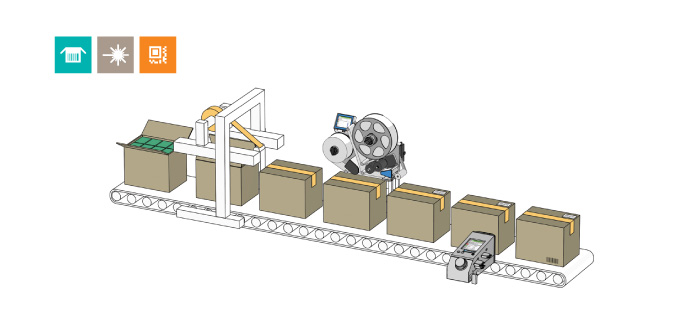

- Case

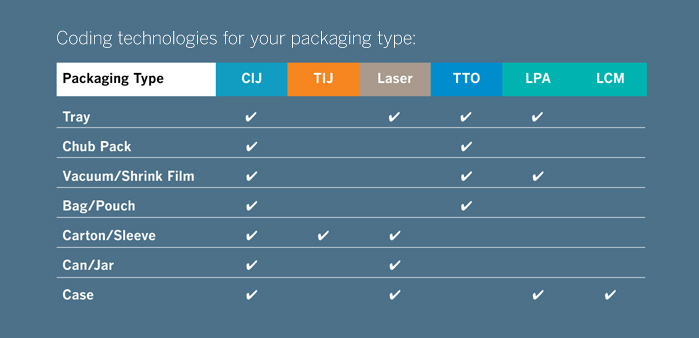

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints.

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Label Printer Applicator (LPA)

Prints and places labels of various sizes on multiple package types.

Changing consumer preferences and the goal of extended shelve life drive constant change in films for the meat and poultry industry. Moreover, coding more information is not only required by law but is becoming an expectation of consumers. TTO and LPA are two technologies that can help you comply with these requirements while maintaining superior printing that conveys your high-quality product.

Continuous Inkjet

(CIJ)

- Condensation-resistant inks help ensure code stays in place when printed on any part of the package surface.

- Changing codes is easy through a user-friendly message creation interface or connection to networking software

Thermal Transfer Overprinting (TTO)

- Print on either stationary or moving products, and it is possible to switch between the two types of printing

- Can be printed on almost any colour, including dark films

Label Printer Applicator (LPA)

- Variable information such as weight, ‘sell-by’ date and price can be printed for each package prior to automatic placements

- Can print customised labels and eliminate the need for manual handling

Chub packs provide ground meat with an easy-to-transport, solid shape and are used in both retail and commercial channels. Due to the lack of air inside a chub package, they often have a longer shelf life for ground meats or poultry versus trays and can be easily frozen.

Continuous Inkjet

(CIJ)

- 316 stainless steel construction can help prevent rust and corrosion in washdown environments

- CleanFlow™ printhead technology reduces printhead maintenance intervals helps provide clear codes even near package seams

Thermal Transfer Overprinting (TTO)

- Clear, easy-to-read codes that are durable in freezing temperatures

- Integrates directly into the line and prints on the film prior to filling

- Ideal for printing nutrition facts, safe handling instructions, and other product information

Managing multiple pre-printed films for multiple products running on the same line can be cumbersome and costly. TTO gives you the capability to print product information during packaging and vary mark content to limit pre-printed film variations. TTO can print high resolution logos, bar codes and product information, giving you the ultimate in flexibility and efficiency.

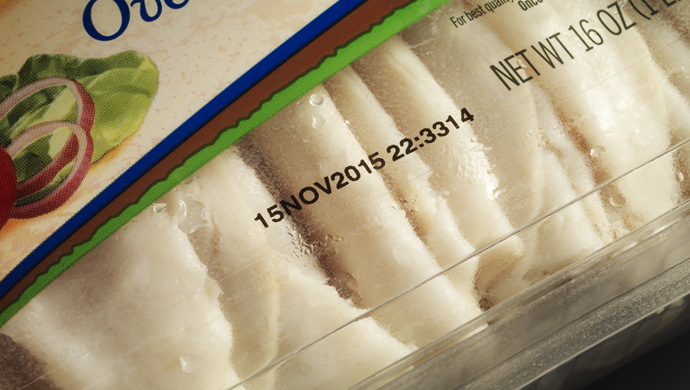

Continuous Inkjet

(CIJ)

- Versatile coding solutions for nearly every package material, size or colour

- Broad fluids portfolio with over 175 ink offerings including odorless and non-MEK inks

Thermal Transfer Overprinting (TTO)

- Clean, clear coding of information such as nutrition facts, allergy information or product logos

- Excellent adhesion on film because printing takes place prior to the vacuum process

Make sure your coding doesn’t detract from your great package styling. Consider coding during the design process and then choose the optimal coding technology for your specialised package

Thermal Transfer Overprinting (TTO)

- Print product information during packaging and help eliminate the need for pre-printed films

- Directly integrates with vertical form fill seal machines (VFFS) to produce high quality codes

Continuous Inkjet

(CIJ)

- Particularly useful for more complicated applications such as preformed pouches and bags with very thick resealable zippers

- Can be seamlessly integrated with a bag sealer to help increase efficiency and create clear, readable codes

Laser Marking Systems

- No inks or fluids required, thereby eliminating the potential of ink affecting product integrity

- Videojet fume extraction systems help keep the production environment and marking lens clean

Coders are integrated either directly with a cartoner or on the outfeed conveyor after the carton has been filled and sealed. Although integration directly with the cartoner can require more planning, it offers you considerable benefits. These include more consistent coding due to more precise material handling and the use of existing guards on the machine.

Laser Marking Systems

- Extremely high resolution codes for printing country of origin or other product information on cartons

- Comprehensive portfolio of laser accessories including lenses and beam turning units to simplify line integration and maximise laser performance

Continuous Inkjet (CIJ)

- Specialty inks can create contrast and are ideal for use on virtually all carton materials, including aqueous overcoats and other varnishes

- Coloured inks can be used to create contrast on different colored cartons

Thermal Inkjet (TIJ)

- Creates complex, detailed messages, bar codes and 2D codes, ideal for retail-ready packaging

- Compact design for simple line integration and flexible communication choices for ease of use

The selection of a coding technology and fluids, when required, should be based on the unique needs of your business. Substrate and environmental considerations, stringent sanitation requirements, and heat and humidity resistance can make that selection process more challenging. With over 40 years of experience and more than 600 specialised inks, our technology experts can help you find the right solution for your production.

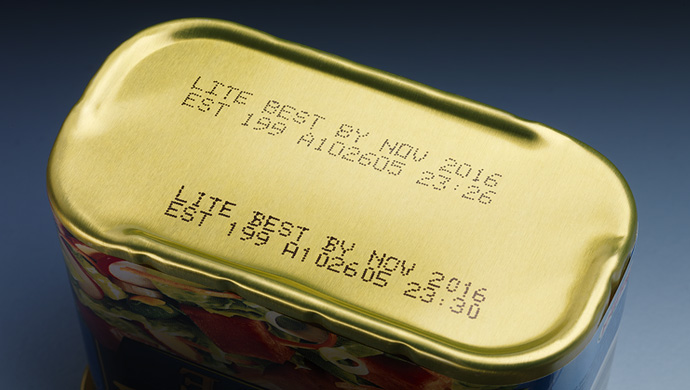

Continuous Inkjet (CIJ)

- Codes can be printed with special inks that change color to confirm that products have passed through a critical retort process

- Smart Cartridge™ fluid delivery system means virtually no mess, no waste, and no-mistake fluids replenishment

Laser Marking Systems

- Versatile laser marking systems are easily adjusted for varying package sizes

- Scribing technology and large marking fields provide excellent code quality

- Fiber laser marking systems are able to code on metal surfaces

Printing lot, batch and supplier-specific information on your cases creates a traceability point that is visible to your warehouse, wholesaler and retailer. This information provides vital product information, allows for rapid identification and helps to move your product quickly through your supply chain. In addition, printing this information directly on the case helps reduce pre-printed case related costs by using generic cases and printing different trading partner’s information on demand.

Large Character Marking (LCM)

- Eliminates the cost, storage and management of labels, and need for customer-specific pre-printed cases

- A unique, automatic, patented printhead micropurging process helps keep the printhead free of debris for best print quality

Label Printer Applicator (LPA)

- Automatic application of high quality printed labels, designed for ease of use and low maintenance

- Direct Apply labelling can increase performance with on-demand label application up to 150 packs per minute (typical 4”x6” label)

Laser Marking Systems

- A DataLase® (a contrast enhancer) coated case marked with a laser will produce a dark black and extremely high resolution print

- Especially useful for water-resistant coated boxes, as it enables clear, dark printing without damage to the protective coating

Thermal Inkjet (TIJ)

- High resolution, ink-based printing with no wear parts, minimising maintenance and related downtime

- Ideal for non-porous substrates, MEK-based inks help ensure clean codes and good code recovery even after line interruptions

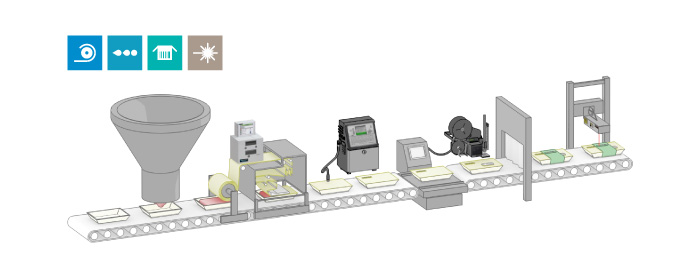

- Horizontal Form Fill Seal

- Vertical Form Fill Seal

- Case Packer and Sealer

Although coding downstream in the conveyor is possible, the highest quality codes are typically obtained by coding on the film prior to packaging. Good integration is key.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

Whether intermittent or continuous motion, Videojet has a range of printers to address the growing complexity of VFFS bags and pouches. Our technologies can handle unique packaging features like zips and gussets.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

Case printers are best integrated on your conveyor after the sealed case has been discharged. The type and amount of information you want to print on your cases determines which coding solution is ideal for you.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

- Brochures

- Case Studies

- White Paper

- Application Notes

Contact Us

For Sales Enquiries please call us free on: +44 1480 443205

For the main switchboard please call:

+44 (1480) 443160

Press 1 for Equipment Sales

Press 2 for Service, Support, Parts & Consumables

For other departments please use the auto attendant

Join Thousands of Industry Professionals!

Subscribe to our newsletter and stay up-to-date with the latest news, trends, and innovations in the Coding and Marking industry.